home | tumblrblog | musics | electronics | ask | about | more

I’ve had this Harmony Model H400A tube guitar amplifier sitting in my parent’s house for about 8 years or so. My grandfather gave it to me because it was just chilling in his old shed for who knows how long. When I first got it, it turned on fine but had a loud hum and barely cranked out any sound even at full volume. So, I let it continue to sit around and never really thought much about it. I even considered selling it.

Then, after building my first tube amplifier—a Smokin’ Joe II from Weber Speakers—I thought I’d give a try at fixing up my old Harmony. When I got it back from my folks’, it was in even worse condition: when it powered on, it would oscillate loudly and violently at a low hum-frequency until I turned the thing off. Once I checked the tubes with a vintage tube-tester I found in the electronics lab I used to TA for, I decided to totally overhaul the components inside. Even if I did find the cause of oscillation, the old carbon film resistors and ancient capacitors probably didn’t help the noise problems that were occurring back when it sort of worked.

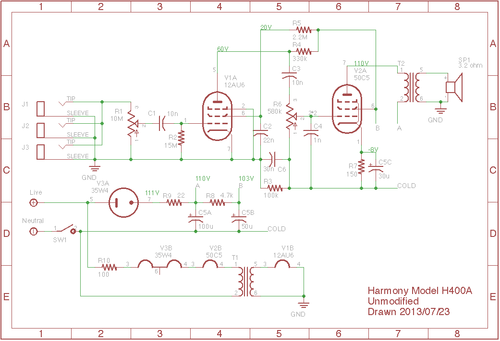

Additionally, the design this amplifier used is sometimes called a “widowmaker”. Basically the idea here is that any electrical device that does not have a power transformer and has a two-prong power cable that is not polarized (meaning that it can be plugged in either way, sort of like many wall-wart power supplies) has the chance of shorting the live wire of the AC plug to the chassis of the amp and anything connected to it. In other words, it may kill you. If you check out the schematic that I drew up of the original circuit below, you can see the neutral line going through a switch, up through a net called COLD, then through a coupling 100k resistor/30n capacitor pair to the ground. If either of those coupling components internally shorts or is leaky, and you plug the amp into the wall “backwards”, you could easily receive an unpleasant shock, or potentially a life-threatening electrocution.

The easiest solution to this problem is to use a polarized 2-pronged AC power cable, but the best solution is to redesign the power supply to work with a 3-pronged power cable. This way, if there is ever a fault in the mains or the circuitry, there is a dedicated path for current to flow to (this is the whole point of three-pronged power cables). There should also be a fuse installed in order to break the circuit in case of a current overload.

The original power circuitry consisted of a simple single-ended tube rectifier, voltage dividers, and filter capacitors to convert the 117V AC supply to 110V DC and 103V DC. The power switch is on the neutral return line, also labeled in my drawing by the net COLD. This design does not lend itself well to modern 3-prong wall connectors, because there should be electrical isolation between the neutral and ground connection. Perhaps a “purist” approach would be to couple the ground prong to the chassis, but then there is still the issue of the potential failure of the coupling resistor and capacitor pair between the neutral and ground. This could cause problems with mains that have been wired incorrectly (these things do happen!).

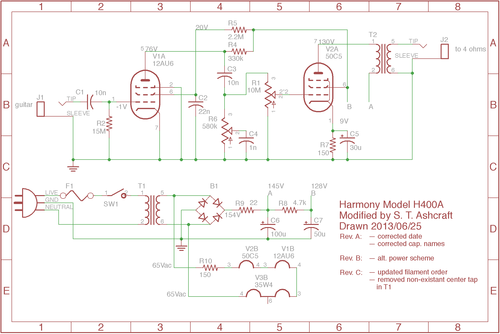

All of these problems are solved with the use of an isolation transformer and a full-wave rectification circuit. The isolation transformer provides electrical isolation between the neutral and the ground, and the full-wave rectifier guarantees the correct polarity from the wall. I used a 1:1 transformer from Triad Magnetics, part number 553-N68X; these are very affordable isolation transformers and can be got from most major electronics suppliers.

Changing the power supply circuit means we have to rethink the filament supply for the tubes. Each tube’s filament requires its rated voltage (approximately the first few numerical digits of a tube’s code), and these tubes also all happen to be rated at the same current, 150mA. This allows them to work well in series with each other. The filaments are basically resistive loads, making the calculation of the extra voltage-dropping resistor easy using Ohm’s Law.

You may notice that I still have the 35W4’s filament in the loop, even though I’m not using that tube for rectification anymore. This choice was made mostly for the convenience; it makes the series resistor value an standard one (and that particular power resistor was just lying around), and kept the tube lighting up, retaining it’s coolness factor.

In the original circuit, the speaker was directly wired to the amplifier. I like the idea of being able to try other speakers if I wanted to, and I never really needed an amplifier with more than one input, so I decided to use one of the inputs as an output jack leading to the speaker. In early pictures of the amp, you can see I straight up plugged the speaker in what used to be a guitar input rewired to be the output. I’ve since then gained access to a drill press, and drilled a hole in the bottom of the chassis for the output jack, as well as mounting holes for the isolation transformer so that it can be mounted closer to the amp and directly to the chassis, which helps with shielding.

Aside from these modifications, I wanted to be as true to the original circuit as possible. What I discovered, however, is that the original design is by its nature not incredibly great. The Volume potentiometer attenuates the guitar signal before it has ever been amplified, which lengthens the amount of wiring that the unamplified signal must pass through which is susceptible to picking up noise. This meant I’d have to have the amp turned all the way up to reach a more ideal signal-to-noise ratio. This may explain why, back when it did work, it was always noisy, even with the volume turned down.

The solution I decided on was simple: I would move the Volume potentiometer after the 12AU6 amplification stage and before the 50C5 power amplification stage, making it more of a master volume knob than a volume knob. This would allow me to directly couple the guitar signal to the grid of the 12AU6 through the input capacitor. This significantly reduced the noise to the point where it was nearly silent when turned down, and barely noticeable when turned all the way up.

Certainly many other modifications could be made. I could replace the 35W4 and use its tube socket for another 12AU6 gain stage. Or I could rework the power supply to incorporate the 35W4 as the rectifier, connect the isolated “neutral” to ground, and reference the filaments to ground which may improve noise. Additionally, there are many options for voicing the tone control in different ways. But for now, I’m content as it is as a little practice amp with plenty of character.

If you have any comments, suggestions, or questions, feel free to contact me via my ask page. Simply include your email address so I can respond.

Here’s a video demonstration of the thing in action:

https://youtube.com/watch?v=4uofpxpeBnw